+420 735 799 290

Call from 7:00 AM to 6:00 PM

Solutions

Products

Cantilever racking

Cantilever racking UNIKANT Mobile cantilever racking MOBIKANT Cantilever racking with extendable consoles Mobile cantilever racking with extendable consolesShelving

Shelving SUPER, UNIRACKRacking with pull-out platform

Storage box with pull-out platform DRIVER BOXTyres storage

Racking and shelving of tyresRacking for moulds

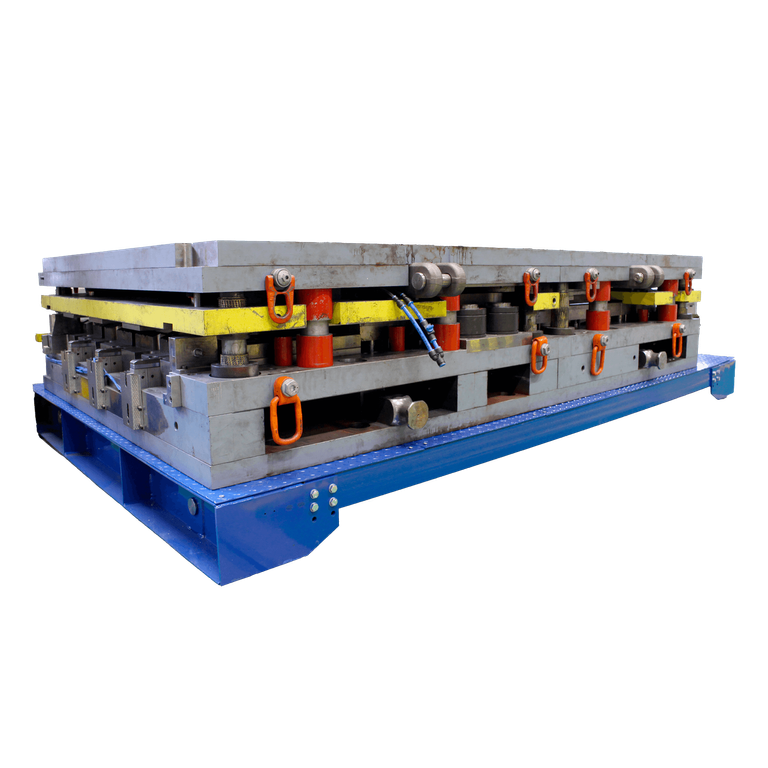

Mould racking MOULDBOX

HOT-LINE Service

+420 735 799 290

Call from 7:00 AM to 6:00 PM

Mould storage racking make use of the vertical and horizontal possibilities of your warehouse. The Mold Box is particularly suitable for moulding, plastics, rubber or sheet metal storage plants. They save space and make efficient use of hall height.

With the Mold Box you have an easy overview of the mould location through the mold location in the information system, managing the mould warehouse, saving time in handling and increasing production productivity. It also provides great protection for expensive moulds from damage and external influences. Safe storage away from the movement of handling equipment, materials and workers. The handling of moulds from the stackers to the presses is carried out using overhead or other types of cranes, which provides greater job safety due to less manual labour and less likelihood of injury when hanging and unhanging the mould. The design of the Mould Box stacker offers direct access to each mould.

Properties

Advantages

Contact our sales for more information for your solution.

Miroslav Hlahůlek

Key Account Manager, Italy

miroslav.hlahulek@kredit.cz

+420 731 478 217